Pipe Mill Equipment

Welcome to the Pipe Mill Equipments section of Divyansh Engineers, where we provide high-quality machinery and innovative solutions for the pipe manufacturing industry. Our extensive range of equipment is designed to meet the demanding requirements of pipe mills, ensuring efficiency, reliability, and superior performance.

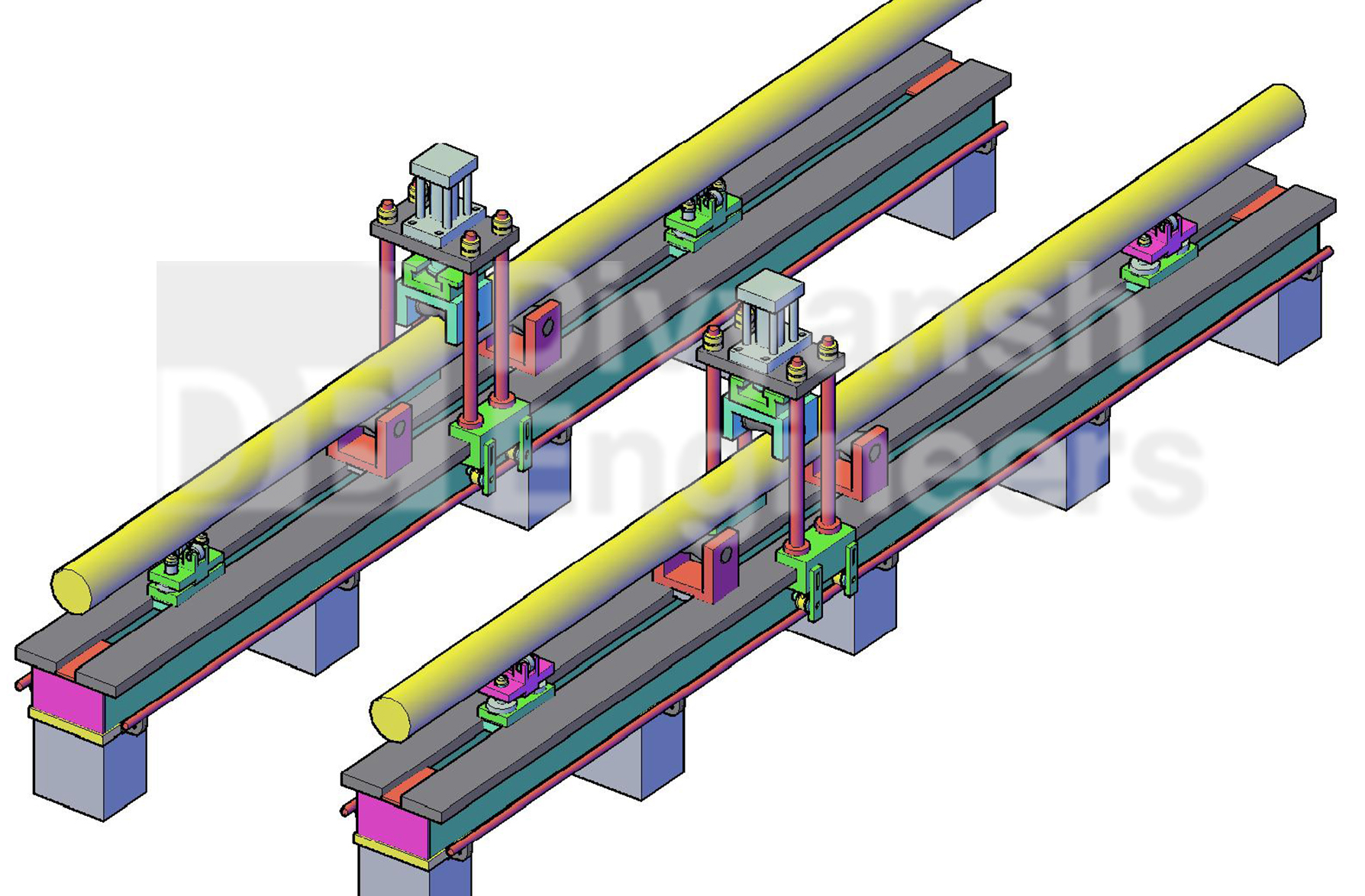

Pipe Trolley cum Rotator

Combines transport and rotation of pipes, enhancing efficiency and reducing manual effort in pipe mills.

Pipe Rotator

Efficiently rotates pipes, ensuring precise positioning and improving workflow in heavy-duty industrial applications.

Pipe Traveller

Ensures safe and smooth transportation of pipes, enhancing efficiency in pipe mills.

Pipe Leveller

Straightens pipes, ensuring uniformity and high-quality results in the manufacturing process.

Pipe Drilling Unit

Delivers precise, efficient drilling of pipes, boosting productivity in high-capacity production environments.

Our Offerings:

1) Pipe Forming and Welding

Pipe Mills: Advanced pipe mills designed for the efficient production of high-quality pipes in various sizes and materials.

High-Frequency Welders: Efficient welders for producing strong and precise welds in pipe manufacturing.

Saw Welders: Versatile saw welders for high-speed and accurate welding operations.

Spiral Pipe Mills: Cutting-edge mills for manufacturing spiral pipes with excellent strength and durability.

2) Cutting and Finishing

Cold Saws: High-precision cold saws for accurate cutting of pipes to the desired length.

Flying Cut-Off Machines: High-speed cut-off machines for continuous cutting during the production process.

Beveling Machines: Efficient beveling machines for preparing pipe ends for welding and other operations.

End Facing Machines: Accurate end facing machines for preparing clean and smooth pipe ends.

3) Inspection and Testing

Ultrasonic Testing Machines: Advanced ultrasonic testing equipment for detecting defects and ensuring the quality of pipes

Hydrostatic Testers: Reliable hydrostatic testing machines for pressure testing of pipes to ensure their integrity.

X-Ray Inspection Systems: High-resolution X-ray inspection systems for internal quality checks of pipes.

Magnetic Particle Inspection (MPI) Equipment: Efficient MPI equipment for detecting surface and subsurface defects in pipes.

4) Coating and Lining

Pipe Coating Machines: State-of-the-art coating machines for applying protective coatings to pipes

Pipe Lining Machines: Advanced lining machines for applying internal linings to pipes to enhance their durability and performance.

5) Handling and Transportation

Pipe Handling Systems: Robust handling systems for the safe and efficient movement of pipes within the manufacturing facility

Pipe Conveyors: Durable conveyors specifically designed for transporting pipes over long distances.

Pipe Lifting Equipment: Reliable lifting equipment for safely handling heavy and large diameter pipes.

6) Auxiliary Equipment

Pipe Benders: Versatile pipe benders for shaping pipes to the desired curvature.

Pipe Expanders: Efficient expanders for increasing the diameter of pipes to meet specific requirements.

Pipe Straighteners: High-precision straighteners for ensuring the straightness and uniformity of pipes.

Explore our range of pipe mill equipment and partner with Divyansh Engineers to enhance your operational efficiency and productivity in pipe manufacturing.

Explore our range of material handling equipment and partner with Divyansh Engineers to enhance your operational efficiency and productivity.